Robots are essential tools in the factory. They have been used to automate the manufacturing process for over fifty years now.

Modern robots have already been embraced by many manufacturing companies and their workers.

Even when many factory workers view robots negatively, their perception changes once they experience the modern collaborative robots.

Collaborative robots are safe to work alongside fro their security technology. They are fast, small, and much easier to use than many other types of robots.

From the many manufacturing companies of different sizes that have already adopted collaborative robots, this is what happens when you introduce robots to your factory.

Improved Morale

Robots handle dull, boring, and monotonous tasks. When these tasks are taken away from the factory worker, there is an improvement in the workers’ morale.

Tasks such as painting, welding, and lifting heavy objects are common tasks in a factory setting. These are repetitive processes that can lead to boredom and loss of concentration. Such tasks cause workers to tire quickly and look forward to their next break. Additionally, tasks assigned to robots may also be harmful and dangerous to human workers. Tasks that can cause disease and lead to increased absenteeism and higher medical insurance payouts.

Once robots are assigned these tasks and human workers assigned other tasks within the factory including manning the robots, there is increased morale to work. There’s a decrease in absenteeism and the rate of accidents and medical payouts reduces.

This then translates into higher productivity and loyalty to the organization.

Enhanced Safety At The Workplace

Robots help to improve safety at the workplace. This is a big driver in boosting the morale of the workers.

Robots, once introduced into the factory can handle as many dangerous jobs as possible. Jobs that may cause diseases such as painting that releases harmful fumes, working with hazardous material, and other risky tasks.

With factory workers no longer handling these tasks, workplace safety is well checked.

The modern collaborative robot, compared to the traditional robot is completely safe. Workers can work alongside the robot without the need for shielding.

Traditional robots were unsafe and had to be kept away from workers. The collaborative robots have an internal safety mechanism that slows down the robot when it’s near a human colleague. Besides, it has smooth edges to ensure that it doesn’t cause injuries when bumped against.

Increase In Productivity

Robots help both small and large companies increase their production capacity. Robots work fast. They also work long hours without the need for a break. Thus robots can produce much more than a team of human workers can.

Coupled with productivity is competitiveness. With robots, companies can produce high-quality products at a low cost. This ensures that companies can deliver to the market affordable products and remain in business.

High-quality products, produced and sold affordably will ensure that the company remains afloat even in tough times.

Human and Robot Collaboration

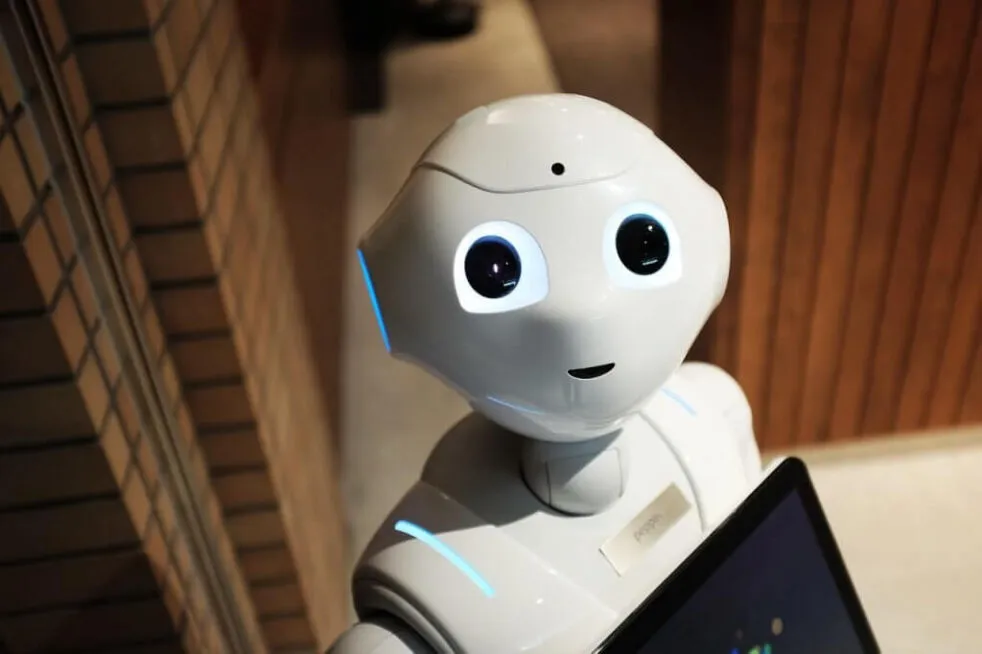

Collaborative robots are the most common robots found in factories for the last decade. They are also the most bought robots in manufacturing over the same period.

Collaborative robots or cobots, enable the collaboration of humans and robots at the workplace.

Human workers and these robots work side by side in the factory. This is made possible by the safety features of the robot. These include a mechanism to slow down or shut the robot down once a human being is too close to it when it’s working.

Human-robot collaboration allows for faster and safer production. It also allows companies to produce high-quality products with robots as quality controllers.

Conclusion

Companies gain many benefits by co-opting robots into their production processes. When put into good use, robots ease the workload on the employees freeing them to do other things in the company. Robots also enable a company to remain competitive and profitable. By enabling it to produce high-quality products for its customers.